Ground Penetrating Radar (GPR) has become the gold standard for scanning concrete because it allows us to “see” through solid structures without swinging a single sledgehammer. It operates by sending high-frequency electromagnetic radio pulses into the material.

When these waves encounter an object or a boundary between different materials—such as the transition from concrete to an air-filled void—they reflect back to the receiver.

How GPR Detects Internal Features

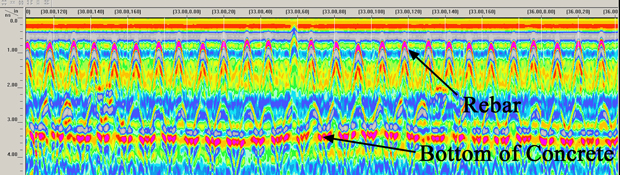

The effectiveness of GPR lies in its sensitivity to changes in dielectric constants. Concrete, steel rebar, and air all have different electrical properties. When the radar wave hits a piece of rebar, it reflects strongly; when it hits a void (an air pocket), the change in wave velocity is distinct, appearing on the technician’s screen as a characteristic “hyperbola” or arch-shaped signal.

Precision and Safety

Unlike X-ray imaging, GPR emits extremely low levels of radiation—less than a cell phone—meaning it can be used in busy environments like hospitals or offices without clearing the building. It provides a detailed map of:

- Rebar and Tension Cables: Identifying the exact depth and spacing to avoid structural damage during drilling.

- Void Detection: Locating “honeycombing” or washouts beneath concrete slabs that could lead to structural collapse.

- Slab Thickness: Measuring the actual depth of a pour when original blueprints are missing or unreliable.

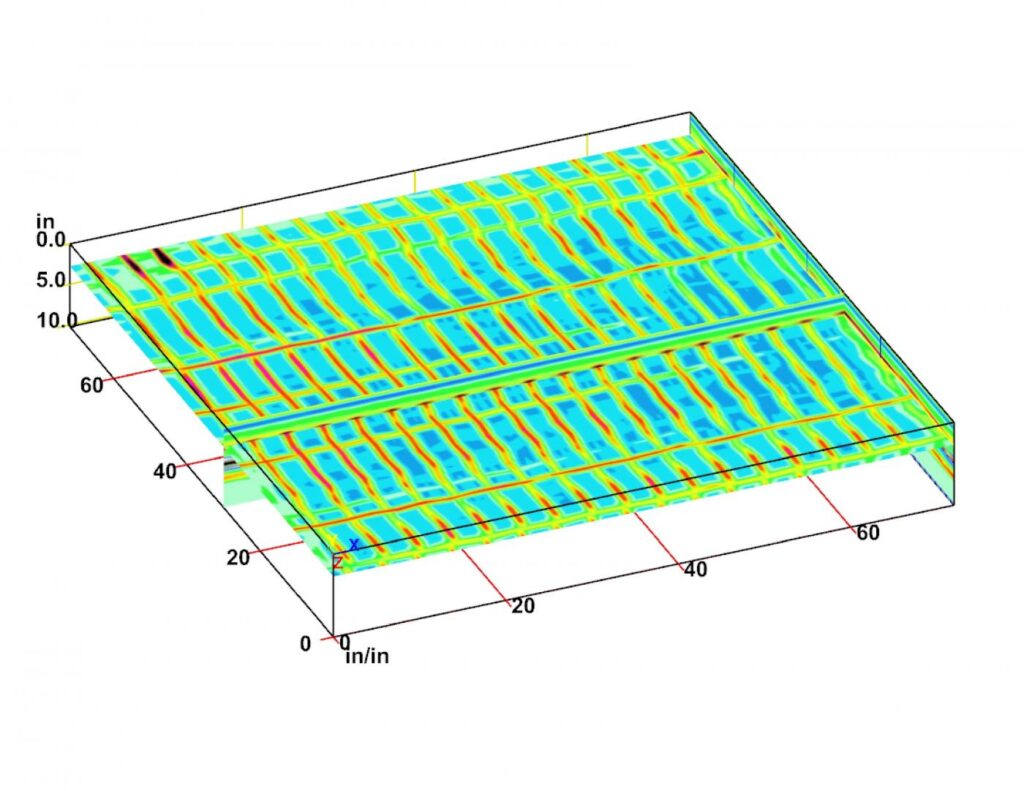

By compiling these scans, engineers can create 3D visualizations of the internal concrete structure, ensuring that any maintenance or construction proceeds with surgical precision and zero accidental “surprises.”