Impact Echo

The Impact Echo Method is used to determine the thickness of concrete, wood, stone, and masonry structural members. It can also be used to determine the condition of concrete when voids, honeycombing and/or cracks are suspected. A solenoid is used to create a high frequency compressional wave that reflects off the bottom of the structure or from a flaw within the structure. The reflected wave is then recorded, processed and displayed. GeoView’s Impact Echo Testing equipment can test concrete from 1.5 inches to 72 inches thick. It meets the standards set forth in ASTM C1383-04.

Ultrasonic Pulse Velocity

The UPV method is used to map and detect voids, honeycombing, cracks, delaminations and other construction related failures in concrete. It can also be used to evaluate conditions in wood, masonry, ceramics, stone and metals. The test is usually performed on columns, beams and walls. The UPV testing equipment consists of a pair of transducers which send and received a 50 kHz compressional wave. The direct first arrival time is recorded and the compressional wave velocity of the concrete is determined. Significant velocity variations across a concrete member indicate problematic areas.

Typical test are performed by placing the source and receiver transducers on either side of the concrete member and collecting data along a systematic grid. For limited site areas, data can be collected on either one side or from the top and one side. Results are typically presented as a contour map of velocity. Concrete thicknesses of up to 6-8 ft can be evaluated. GeoView uses the Olson Instruments UPV-1 Ultrasonic Pulse Velocity system.

Ultrasonic Echo

Ultrasonic Pulse Echo (UPE) technology is the specialist tool used for diagnosing the internal “health” of the concrete itself. Unlike GPR, which uses radio waves, UPE uses stress waves (sound) to penetrate the material. When these sound waves encounter a boundary or a flaw, they reflect back to a multi-channel sensor array. This makes UPE exceptionally good at finding “delamination”—thin horizontal cracks where the concrete layers have begun to separate—as well as “honeycombing,” which occurs when the aggregate hasn’t settled properly, leaving a porous, weakened matrix that GPR might overlook.

Rebound Hammer

The Rebound Hammer, often called a Schmidt Hammer, is the most widely used tool for a quick, “on-the-spot” assessment of a concrete surface’s compressive strength. Unlike GPR or Ultrasonic Echo, which look deep into the slab, the rebound hammer is a surface-interaction tool. It works by hitting the concrete with a spring-loaded mass and measuring how far that mass “bounces” back. This Rebound Value (R-value) is then correlated to the material’s hardness. It is essentially a way of asking the concrete, “How much do you resist me?”—a harder surface reflects more energy, indicating higher strength, while a softer or “chalky” surface absorbs the impact, resulting in a lower R-value.

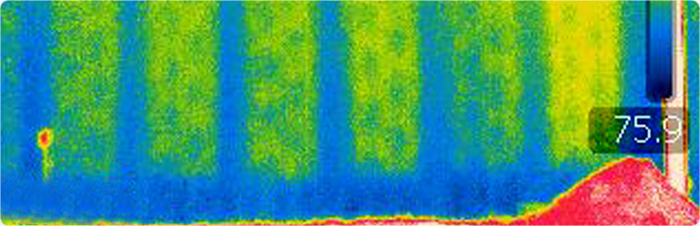

Infrared Concrete

Thermal imaging cameras detect radiation in the infrared range of the electromagnetic spectrum (roughly 9,000–14,000 nanometers) and produce images of that radiation which are called thermograms. The amount of radiation emitted by an object increases with temperature; therefore, thermography allows one to see variations in temperature to a range of 0.1 degrees C. A thermal imaging camera is able to view and record these variations in temperature. GeoView owns and uses state of the art FLIR thermal imaging cameras and our operators are ITC Infrared Thermography Certified based on the requirements outlined by ANSI/ASNT CP-105 and CP-189 of the American Society for Non-Destructive Testing.